- April Fri, 2025

Industries relying on cryogenic gases, efficient monitoring and management of cryogenic tanks are critical for operational success. Traditional methods of monitoring these tanks involve manual data collection, which is often inconsistent, prone to errors, and inefficient. To address these challenges, Ogauge Cryolink introduces an innovative IIoT-based remote monitoring solution that ensures real-time tracking, data-driven decision-making, and enhanced operational efficiency.

The Challenges of Traditional Monitoring Methods

Cryogenic tanks are widely used for storing and transporting liquefied gases such as oxygen, nitrogen, and argon. However, monitoring these tanks manually presents several challenges:

- Inconsistent Data Collection: Manual readings are often skipped or recorded inaccurately, leading to unreliable data.

- High Operational Costs: Manual monitoring requires significant manpower, increasing costs.

- Risk of Emergency Situations: Without real-time monitoring, sudden depletion of gas levels can disrupt operations.

- Inefficient Asset Utilization: Inaccurate monitoring leads to underutilized production and storage assets.

- Lack of Predictive Insights: Historical data is often missing or difficult to analyze, preventing proactive decision-making.

The Ogauge Solution: Smart, Connected, and Efficient

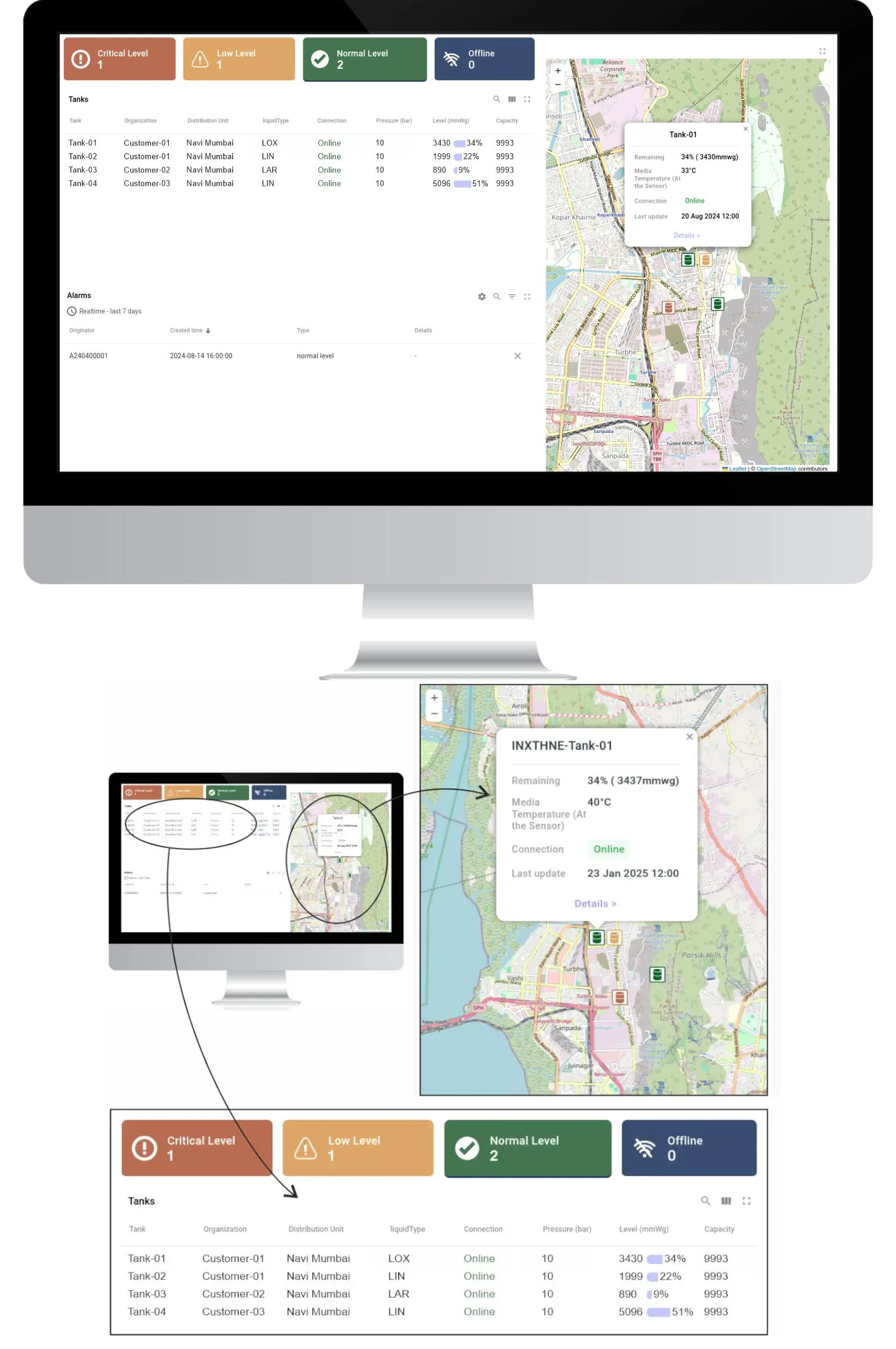

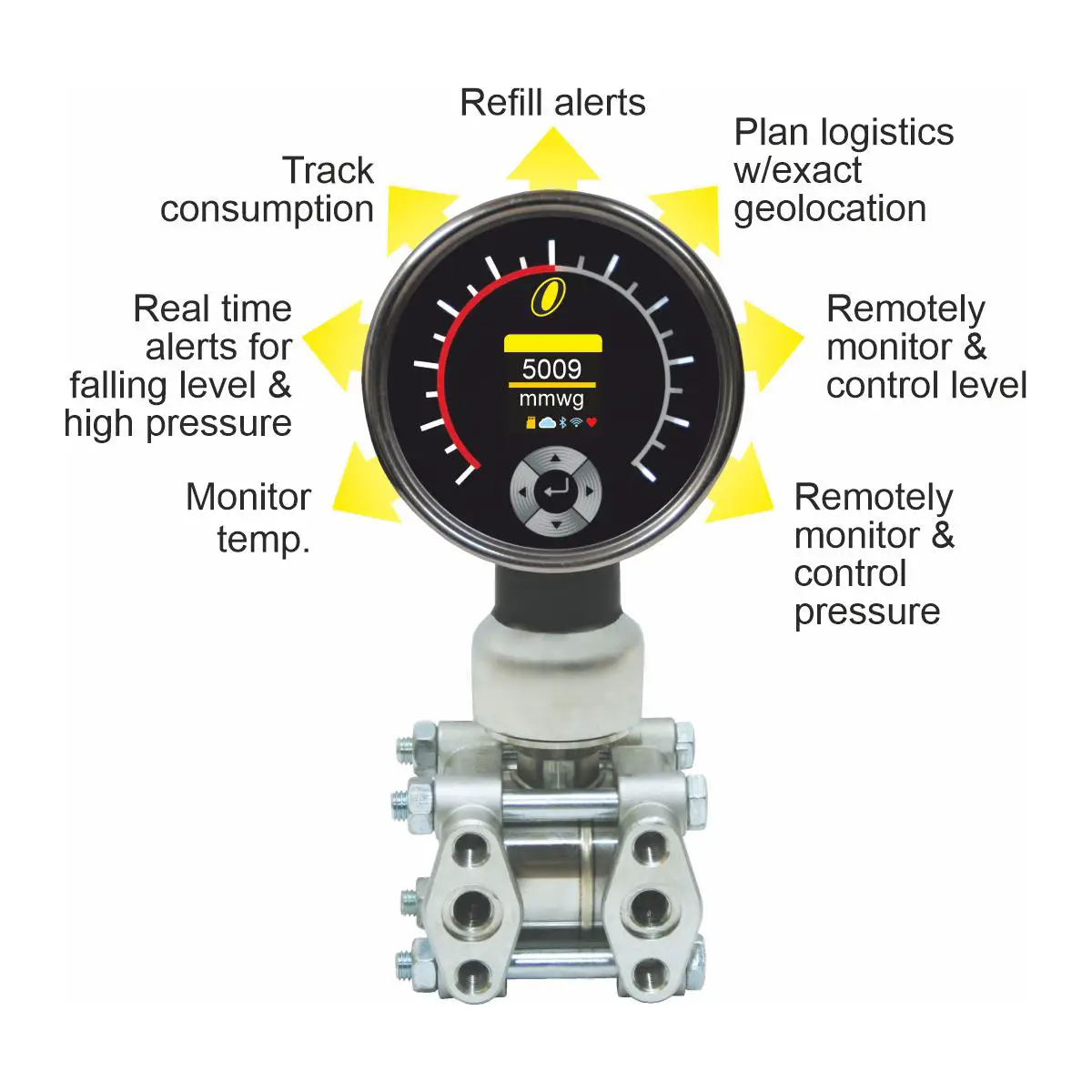

Ogauge offers a digital, cloud-enabled solution that transforms how cryogenic tanks are monitored and managed. Key features include:

- Real-Time Monitoring: Ogauge continuously tracks pressure and liquid levels, ensuring accurate, up-to-date data.

- Automated Alerts and Alarms: With four hard relays, Ogauge sends instant alerts when pressure or liquid levels deviate from set parameters.

- Cloud-Based Data Storage: All readings are securely stored in the cloud, eliminating the risk of data loss and providing limitless storage.

- 24/7 Remote Access: Users can monitor and manage tanks from anywhere through an intuitive web-based dashboard.

- Geolocation Tracking: The dashboard provides precise location tracking of cryogenic tanks, optimizing logistics and delivery planning.

- Predictive Maintenance and Refill Automation: Data analytics help forecast demand, ensuring timely refills and reducing downtime.

- Seamless Integration with SCADA Systems: With configurable analog outputs, Ogauge integrates effortlessly into existing industrial automation frameworks.

- Tamper-Proof Role-Based Access: Different access levels (Operator, Viewer, Admin) enhance data security and integrity.

The Benefits of Using Ogauge

- Enhanced Operational Efficiency: Automated tracking and alerts reduce the need for manual intervention.

- Cost Savings: Eliminating manual data collection lowers labor costs and improves resource utilization.

- Improved Decision-Making: Actionable insights based on real-time and historical data enable strategic planning.

- Better Customer Satisfaction: Predictive analysis helps maintain consistent supply, avoiding emergency shortages.

- Increased Safety and Compliance: Continuous monitoring minimizes risks associated with pressure fluctuations and gas leaks.

About Kaustubha Udyog

Kaustubha Udyog is one of the leading manufacturers of pressure switches for over 30 years. Our customer base spans a wide spectrum of Indian industry. Our products find application in light & heavy engineering industry, automation systems, paint systems, textile machinery, pump systems, boilers, process industry, gas mixing systems and various R & D laboratories, medical equipments, space & defence areas. Alongwith our associate concern M/s Supreme Industries, we cover a wide range of pressure switches from vaccum to 600 bar.

Kaustubha Udyog was started in 1977 in a modest way to manufacture differential pressure switches and low range pressure switches. Since the emphasis was on learning the total concept of pressure switching, the design of the switches & all the testing facilities were manufactured in house. This provided a complete insight into the working of pressure switches & simultaneously ingrained a culture of continuous improvisation of products in the company personnel.

Rigorous quality checks & testing methods led to an inbuilt reliability in every pressure switch that left the factory premises. The result was a growing number of clients & a growing market with cross references. Today, between both the sister concerns, numerous pressure switches are silently working on the field at various sites & on various applications. This troublefree service has given us repeat orders from many a reputed client.

At Kaustubha Udyog , our goal is to develop and manufacture products that are reliable & completely satisfy the needs of our customer. We have subcontracted 100 percent of our parts & hence our workforce comprises only a small core group of efficient, and skilled employees. This provides us a great flexibility for capacity expansion for many pursuant benefits.

Apart from our standard range of products, we can also design instruments to meet your particular requirements. Please send us your requirement in brief to asses the initail feasibility. A lot of combinations in the existing product range are possible, which may be solution to your specific needs.

Transform Your Cryogenic Tank Management with Ogauge

With its advanced IIoT technology, Ogauge revolutionizes cryogenic tank monitoring, offering an intelligent, cost-effective, and scalable solution. Whether you are a gas manufacturer, distributor, or end-user, adopting Ogauge can significantly enhance your operational capabilities and bottom lines.

Experience the future of cryogenic tank monitoring today. Visit www.ogauge.io to learn more and get started.